Why choose AODD pumps over gear pumps: key advantages explained

In various industries, selecting the appropriate pump technology is crucial for efficient fluid handling. Air-operated double diaphragm (AODD) pumps have gained prominence due to their versatility and reliability. This article delves into the key features of AODD pumps for various industries, highlighting their advantages over traditional gear pumps.

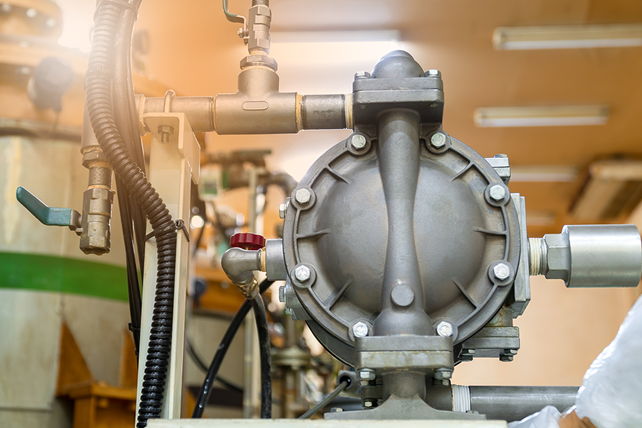

Understanding AODD pumps

AODD pumps are a type of positive displacement pump powered by compressed air. Their unique design consists of two diaphragms that move back and forth, creating suction and discharge cycles. This mechanism allows them to handle a wide range of fluids, including viscous, abrasive, or shear-sensitive substances.

One of the most distinctive aspects of AODD pumps is their ability to run dry without damage and their self-priming capabilities, making them ideal for applications where suction lift is required. These pumps also offer a seal-less design, which reduces the risk of leaks and contamination, an essential feature in industries such as pharmaceuticals, food processing, and chemicals.

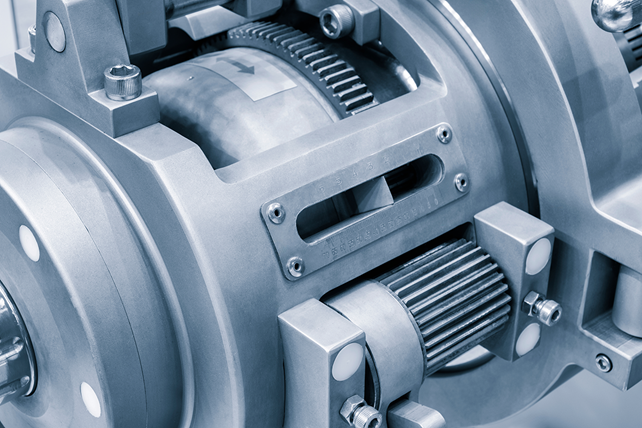

Limitations of gear pumps

Gear pumps, while effective in certain applications, come with notable limitations that make them less suitable for demanding or variable conditions. Some of the key drawbacks include:

§ Sensitivity to abrasives: Gear pumps struggle with fluids containing solid particles, which can cause excessive wear and tear on the internal components.

§ Inability to run dry: Running a gear pump without fluid can cause serious damage, leading to expensive repairs or replacements.

§ Limited viscosity range: Gear pumps typically cannot handle high-viscosity or variable-viscosity fluids as efficiently as AODD pumps.

§ Prone to leakage: Due to their mechanical seals, gear pumps are more likely to develop leaks, which can pose safety and environmental hazards.

§ Higher maintenance requirements: The complex gear mechanism requires regular maintenance, making operational costs higher over time.

Advantages of AODD pumps over gear pumps

1. Dry running capability

AODD pumps can operate without fluid for extended periods without sustaining damage. This feature is particularly beneficial in applications where intermittent flow or unexpected dry running may occur. Gear pumps, on the other hand, will fail if run dry, requiring constant monitoring.

2. Self-priming functionality

Unlike gear pumps, which require external priming, AODD pumps have excellent self-priming abilities. They can lift fluids from depths of up to 6-7 meters, making them ideal for applications requiring suction lift, such as tank emptying and underground fluid transfer.

3. Versatility in fluid handling

AODD pumps can manage a wide range of fluid types, including:

§ Corrosive and hazardous chemicals

§ Shear-sensitive products

§ High-viscosity fluids

§ Liquids containing solids or particulates

This versatility makes AODD pumps a superior choice over gear pumps, which often struggle with fluids outside a narrow range of viscosity and cleanliness.

4. Ease of maintenance

Due to their simple design with fewer moving parts, AODD pumps require minimal maintenance compared to gear pumps. There is no need for costly mechanical seals or lubrication systems, and routine maintenance can often be performed without specialized tools.

5. Explosion-proof and safe for hazardous environments

Since AODD pumps are powered by compressed air instead of electricity, they are intrinsically safe for hazardous or explosive environments. This feature makes them highly preferred in chemical plants, mining operations, and oil and gas industries, where electrical equipment could pose ignition risks.

6. Cost-effectiveness over time

While AODD pumps may have a slightly higher upfront cost, their lower maintenance requirements, durability, and reduced risk of downtime make them more cost-effective in the long run compared to gear pumps.

Applications of AODD pumps in various industries

Due to their superior fluid handling capabilities, AODD pumps are widely used across multiple industries, including:

1. Chemical industry

§ Safe transfer of acids, solvents, and corrosive chemicals

§ Leak-free operation ensures environmental and worker safety

2. Food & beverage processing

§ Handling of thick fluids like syrups and sauces

§ Compliance with sanitary and hygiene standards

3. Pharmaceuticals & cosmetics

§ Ideal for shear-sensitive liquids and creams

§ Prevents contamination with seal-less design

4. Mining & construction

§ Effective pumping of slurries, wastewater, and abrasive materials

§ Explosion-proof properties for underground operations

5. Oil & gas industry

§ Handling of petroleum-based liquids and refined fuels

§ Safe use in flammable environments

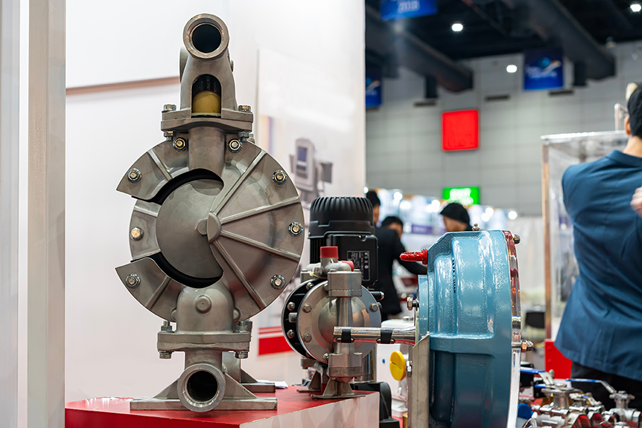

Why AODD pumps are the superior choice

When comparing AODD pumps to gear pumps, it becomes evident that AODD pumps provide greater versatility, reliability, and cost-efficiency. Their ability to handle diverse fluids, run dry, self-prime, and operate safely in hazardous environments makes them an ideal choice across multiple industries.

For businesses looking to enhance operational efficiency, reduce maintenance costs, and improve safety, AODD pumps present a superior alternative to traditional gear pumps.